我们日常生活中的建筑用砖一般有红砖、青砖以及混凝土砖,但你听说过“月壤砖”吗?

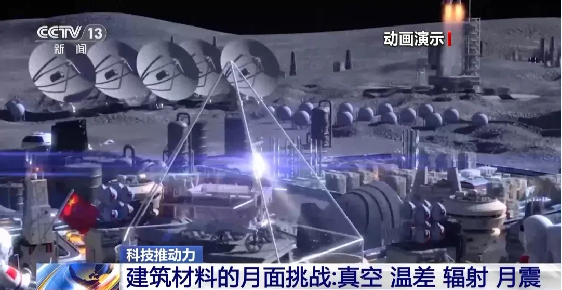

所谓“月壤砖”,是我国科学家模拟月壤成分烧制而成的,拟用于未来建造月球基地。再过一段时间,这种“月壤砖”就将搭乘“天舟八号”货运飞船飞向中国空间站,到太空去做暴露实验。

Bricks made from simulated lunar soil, a potential building material for future habitats on the moon, will be sent to China's space station aboard the Tianzhou 8 cargo spacecraft for exposure experiments.

“月壤砖”跟普通砖有何不同?

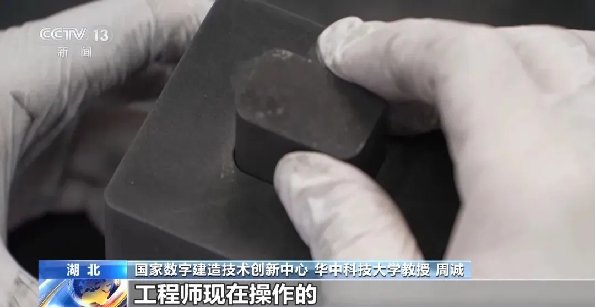

据国家数字建造技术创新中心、华中科技大学教授周诚介绍,“月壤砖”呈榫卯结构,密度与普通砖块相当,抗压强度却是普通红砖、混凝土砖的三倍以上,相当于每平方厘米能承受1吨多重量。

The bricks made from simulated lunar soil have a density comparable to that of ordinary bricks, but their compressive strength exceeds that of standard red bricks and concrete bricks by more than three times, with one square centimeter able to support over one ton of weight, said Zhou Cheng, a professor from National Center of Technology Innovation for Digital Construction.

未来月球基地的建造中,可能采用这样的结构形式进行拼装建造。

“月壤砖”需要经受住怎样的考验,才能肩负起月球盖房子的重任?

月面月昼温度超过180℃,月夜又到-190℃,想要盖房子,首先要接受温度剧烈变化的挑战。

Building a house on the lunar surface could face challenges due to drastic temperature changes on the moon, with temperatures exceeding 180 C during lunar days and reaching -190 C at lunar night.

因为没有大气保护,大量宇宙辐射和许多微陨石会撞击月球表面。

Without atmospheric protection, significant levels of cosmic radiation and many micrometeorites would also hit the surface of the moon.

同时还有震动频率高的月震。

And there is frequent moonquake activity.

这些都会对月面建筑材料的力学性能、热学性能和抗辐射性能提出苛刻要求。

All of these will place demanding requirements on the mechanical, thermal and radiation resistance properties of lunar surface construction materials.

“月壤砖”为何要去中国空间站?

为了验证“月壤砖”的性能,近日,“月壤砖”样品要搭乘“天舟八号”货运飞船前往中国空间站。在完成太空实验后,第一块“月壤砖”预计将于2025年年底返回地球。

The lunar bricks will be sent to China's space station aboard the Tianzhou 8 cargo spacecraft to verify their mechanical and thermal performance, as well as their ability to withstand cosmic radiation. The first lunar brick is expected to return to Earth by the end of 2025.

专家告诉记者,“月壤砖”的太空之旅有三大关键性能要验证,包括:

“月壤砖”的力学性能。太空环境下,样品的力学性能会不会退化十分关键。

“月壤砖”的热学性能的变化。

辐射作用对“月壤砖”的影响。因为月球是真空环境,存在大量宇宙辐射,所以“月壤砖”能否经受住宇宙辐射作用,也非常值得验证。

Zhou outlined three key properties of the bricks that will be verified, including the potential degradation of their mechanical properties, their heat preservation and insulation effectiveness, and their ability to withstand cosmic radiation on the moon.

“月壤砖”是如何炼成的?

月球表面复杂的环境对“月壤砖”的性能提出了极高的要求,“月壤砖”是怎么炼成的呢?周诚介绍,“月壤砖”采用真空热压烧结的方式成型,整个过程大概分为三个步骤。

The whole process of making such bricks by vacuum hot pressing and sintering is divided into three steps, Zhou explained.

第一步,先把模拟月壤进行称重,按照重量放入模具,因月壤非常松散,所以需要在模具容器里进行压制。

Researchers need to weigh the simulated lunar soil and then place it in the mould according to its weight. They have to press it into the mould container as the lunar soil is very loose.

压力施加完毕后,工程师会把压制成型的、带有模拟月壤的模具放到真空热压炉中,加上隔热设施,将它升温烧结。

The researcher will then put it into the vacuum hot-pressing furnace. After locking the whole vacuum experimental device, it can be heated up and sintered.

第三步,对“月壤砖”进行高温烧制。

The lunar soil material that the researchers modeled in the lab is similar to the Earth's soil, which is dispersed. To process it, researchers must subject it to high temperatures.

“月壤砖”是以100%原位成型的工艺方法制造的,整个过程中没有任何其他材料添加物。这也是在未来月球基地建造中的一个非常有潜力的建造方式。

Zhou noted that the process does not involve any additional material additives, making it a highly promising construction method for future lunar base development.

在月球上就地取材

在介绍“月壤砖”制作流程时,科研人员提到一个词——原位成型工艺方法。也就是说,将来建设月球科研站时,可以在月球上就地取材,直接利用月壤、太阳能、矿产等月面原位资源来盖房子,无须再从地球上运输预制建筑构件。这样能极大降低月面建造的成本。这些模拟“月壤砖”在太空暴露实验后,将为未来在月建设积累科研数据,从而优化实际方案。

These simulated bricks will be exposed to experiments in space to accumulate scientific data for building houses on the moon in the future, so as to optimize the actual scheme.

来源:中国日报双语新闻